AUTOMATION – MACHINES AND SYSTEMS

Each automatic machine is developed, designed and built according to the technical specifications and the customer’s production system following the principles of productivity, ergonomics, ease of use, adaptability to customer needs, safety and environmental standards.

Some examples are listed below:

AUTOMATIC ASSEMBLY MACHINES

Most of these machines perform tests and assembly checks on the line (with automatic reject ejection) for a 100% check of the product.

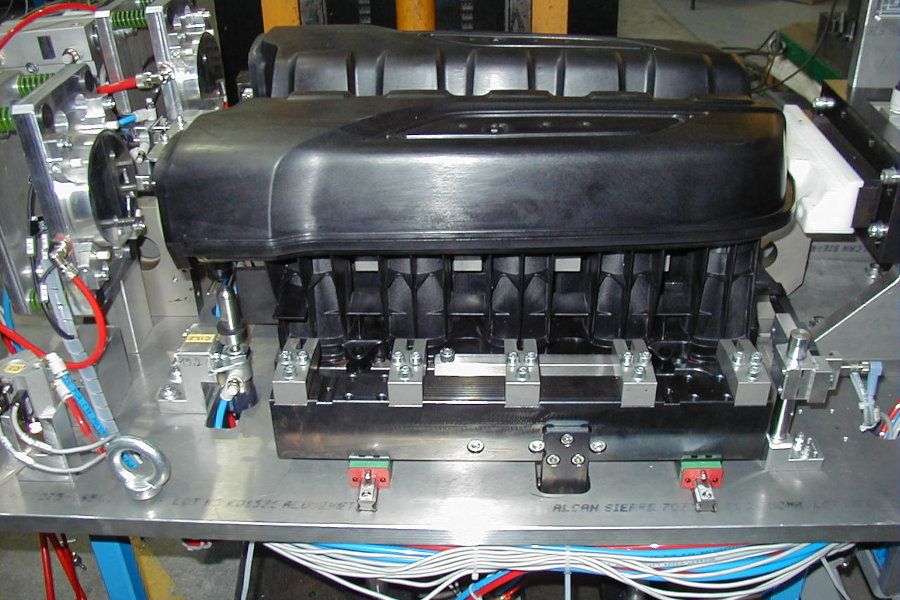

TESTING MACHINES

For leak testing of various components such as car oil tanks, hydraulic process valves, small electro-welded tanks.

MACHINES TENDING INJECTION MOULDS

With automatic magazine-style dispenser, for insertion of components to be overmoulded into the mould, with the simultaneous extraction of the finished product and its testing, also through the use of anthropomorphic robots.

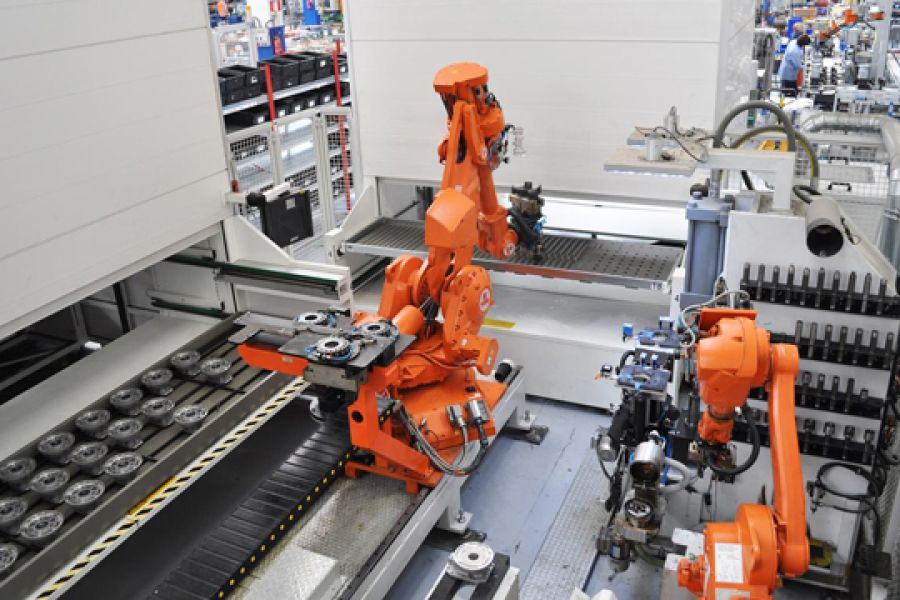

ROBOTIC ISLAND SYSTEMS

For handling, palletising, loading and unloading of existing machining centres or systems.

SPECIAL MACHINES FOR MECHANICAL PROCESSING DEDICATED TO THE PRODUCT

Such as machines for cutting particular profiles, welding plastic tanks, mechanical processing of injection moulded plastic components, bending lines for sheets, and finishing machines for metal components.